It is the principal of marketing to extol one’s virtues, including a healthy amount of exaggeration, therefore it should come as no surprise that the Mesker companies touted their products as the most modern and affordable solutions for commercial building facades on the market. It also stands to reason that such remarkable goods had to be produced in equally modern and impressive facilities that likewise provided another bragging-rights opportunity to distance the competition.

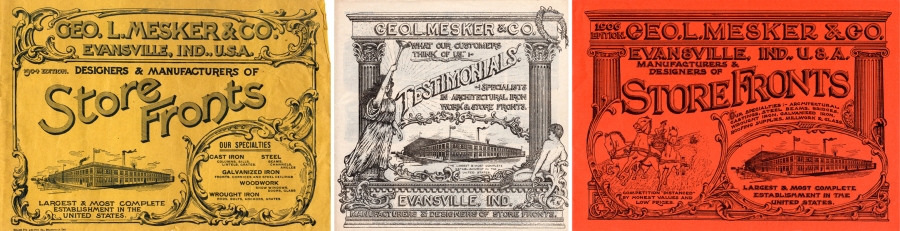

Beginning in the 1890s, George L. Mesker & Co. of Evansville, Indiana, made a bold assertion that it had the best and largest storefront manufacturing facility in the country. Whether true or not was irrelevant—the claim read as fact when prominently displayed along with a rendering of the building on the company’s catalog covers and stationery. Faced with such a declaration, a store owner and prospective Mesker client at the turn of the 20th century would have no way of verifying its veracity. And while as a marketing slogan its effect may have been trivial, an efficient factory with capacity to supply products on a national scale was absolutely necessary to the company’s success.

The self-proclaimed “largest and most complete plant in the United States” had humble beginnings. In fact, starting out George Mesker did not even have his own factory, working out of his father’s space at J.B. Mesker & Son at the corner of Fourth and Division Streets (present-day Market and Court). In 1885, he eventually opened his own place at the intersection of Ingle and N.W. First Streets, taking over a former foundry building of J.B. Mesker & Son that was either sold or gifted to him by his father. Even after he ventured out on his own, however, George periodically used a rendering of his father’s building in his own marketing; after all, two factories are more impressive than one. (Tapping into the family’s architectural sheet-metal work pedigree would become a common theme for all of the Mesker businesses and appears to have been sanctioned by the father who, above all, wanted his sons to succeed.)

The flourishing mail-order front business allowed George to overcome what could have been a major setback—his original factory burned in a fire on October 16, 1891. Mesker’s 1892 catalog described the situation as follows:

During the past year we were compelled to subject some of our customers to a little delay, on account of the burning of our works, which occurred on October 16. We were not to be daunted, however, by this circumstance. We had a temporary building up and were running a week after the fire. From the ashes of this conflagration has arisen the magnificent plant of which we show a picture on the first page.

The new building was indeed impressive. Rather than a haphazard collection of smaller buildings, the new three-story structure filled the corner lot, fronting 310 feet along Ingle and 150 feet along N.W. First. At the north section’s main corner was an office, with the foundry, blacksmithing, casting cleaning, and galvanized iron work spaces completing the first floor. Woodworking was on the second floor and painting and trim work on the third. The south half of the plant was used as warehouse space. The exterior’s High Victorian styling was very much in vogue and appropriately Mesker clad the facades in his sheet-metal products. Corner turrets and a central tower with a drive through bay added to the panache. Subsequent catalog covers began to label the plant as the “largest and most complete establishment in the United States” and virtually the identical image of the building was proudly and continuously reproduced from year to year on all marketing collateral, including letterheads and envelopes. This was very much typical of business marketing materials of the era, as was a visual trick of rendering the foreground figures and vehicles at a reduced scale, to make the subject building appear larger and even more impressive.

Each year’s catalog boasted of the company’s capabilities, due in large part to the factory. From the 1895 edition:

We have the best and largest equipped establishment in the United States for the manufacture of Store Fronts. We make all the Cast-Iron, Wrought-Iron, Galvanized-Iron and Wood work for our fronts in our own factories, and are not dependent on other manufacturers for our supplies. There is no other firm in the country furnishing Store Fronts which is not compelled to buy some part of the work from other manufacturers. Persons who buy fronts from us get them from first hands, all the work being made under one supervision, and thus they are sure to get work accurately fitted and harmonious in construction. This cannot be assured by parties furnishing fronts who are compelled to buy some parts of the work from other factories.

Business continued to thrive until another devastating fire in December of 1900 destroyed the plant, which led to yet another rebuilding, completed in the summer of 1901. While the new factory was only two stories tall, it was decidedly more modern in appearance than its Victorian predecessor. Red brick was paired with Mesker’s pressed-metal window bays and cornice, whose designs were refined since the early 1890s. The interior construction was made fireproof with steel columns and girders and a concrete first floor, where the foundry and structural iron work was handled. Second level had tongue and groove wood floors and housed wood working machinery and the tin shop for galvanized sheet-metal work. Warehousing was moved to a one-story building at 305 N.W. First Street, catty corner from the plant. This building was clad in galvanized sheet-metal panels and cornices identical to those offered in the company’s catalogs.

Unfettered by the tragedy, or perhaps strengthened as a result, Mesker’s boastful claims continued. From the 1911 catalog:

We have the largest and most complete plant in the United States for the manufacture of store fronts, equipped in every department with the latest labor saving machinery, situated in the very heart of the coal, lumber, iron and glass district, with the best railroad and river facilities for shipping.

The equipment was also praiseworthy. Of the galvanized iron department, Mesker wrote:

The equipment in this department can not be surpassed. Our special machinery for forming mouldings, our presses and hammers for stamping and embossing ornamental work are of the best and most modern. In addition, we have a large force of skilled galvanized iron workers.

While Mesker acquired the adjacent property of the Kratz Brothers Machine Shop and extended its new plant along N.W. First Street the length of the block, the southern half of its lot along Ingle was vacated. In this area, a four-story warehouse was constructed in 1905 by Ragon Brothers Wholesale Grocers. Utilizing Mesker’s galvanized sheet-metal ornamentation for the window bays and cornice, the building was reportedly the largest wholesale grocery in Indiana. It was later occupied by Bement & Seitz Wholesale Grocers and at some unknown date (but prior to 1957), it was acquired by Mesker and became part of its plant. Curiously, years before the acquisition took place Mesker’s graphics already included the taller structure as part of its holdings, displaying it adjacent to the plant as if it was part of it. Some images were brazen enough to include signs of Geo. L. Mesker & Co. rendered across the top! Beyond wishful thinking, this could have been another subtle tactic to impress would be customers across the country—only locals would know that Mesker’s iron works did not extend to include this warehouse.

.jpg)

In the 1950s, the plant’s exterior was modernized—except for the cornice, the outdated pressed sheet-metal ornamentation was discarded and most of the double-hung wood windows were replaced with multi-light industrial steel sash. The former Ragon Brothers/Bement & Seitz Warehouse was joined with the plant and was used for storage. Another large steel warehouse was constructed to the rear, at the corner of N.W. Riverside and Clark (Pine), filling the remainder of the city block. It had a steel frame and a metal roof deck supported on steel trusses, while the exterior featured continuous multi-light metal windows and asbestos siding. Although the company’s business model shifted entirely to structural steel fabrication, the focus of marketing remained the physical plant and its modern, efficient equipment.

A reorganization in 1970 resulted in a new name—Mesker Steel, Inc.—and one final exterior remodeling. The red brick exterior was painted Williamsburg green to match the green concrete shingles of the new mansard roof while remaining wood windows were replaced with steel. The main entrance was moved over one bay and redesigned with stucco panels, wrought iron, and a large sign above a flat metal canopy. Even in this era, a rendering of the plant was included in the company brochures, along with photographs of the plant’s interior. The production space grew to 143,000 square feet and accommodated numerous fabricating equipment including overhead cranes, spacers, punchers, drills, shears, saws, welding machines, a press brake, plate roll, milling machine, a sandblaster, and airless paint sprayers. Despite the impressive facilities (Mesker had another smaller plant in New Albany, MS), after several years of financial decline, Mesker Steel was sold in 1974 to the Fabsteel Company, a structural steel fabricator for the petrochemical industry. While Fabsteel envisioned the Mesker plant to specialize in steel fabrication for nuclear power plant construction, the Evansville foundry closed in 1981 after 96 years of operation. It was purchased by Industrial Contractors, Inc. in 1984 for use as a warehouse. The property sat mainly vacant until it was razed in 1992 to make room for the Casino Aztar Hotel, and more precisely for its multi-story parking deck. Whether it ever was the largest and most complete iron works in the United States remains unverified, but its success is beyond reproach—thousands of galvanized sheet-metal fronts, cast iron columns, and structural steel components bearing the name of Geo. L. Mesker & Co. were shipped from the corner of First and Ingle to all parts of the country.

.jpg)

.jpg)

What a cool article. I grew up in Evansville, this took me back home a little bit 🙂 Thanks for sharing!

Thank you. I’m glad you liked it!

Hello, I believe I have a building that might have mesker ornamentation. They aren’t quite the typical details I briefly came across in your compilation of images, but they are similar. In any case, my building is beautiful. We are just beginning to look into doing some work on the exterior. I was researching any information that would help me understand what we are up against. Your research is amazing!

Thank you! I’m glad you found this helpful. I’d be happy to look at the photos of the building and let you know if it is a Mesker facade or not. If you’d like, please e-mail me at bryjka@hotmail.com